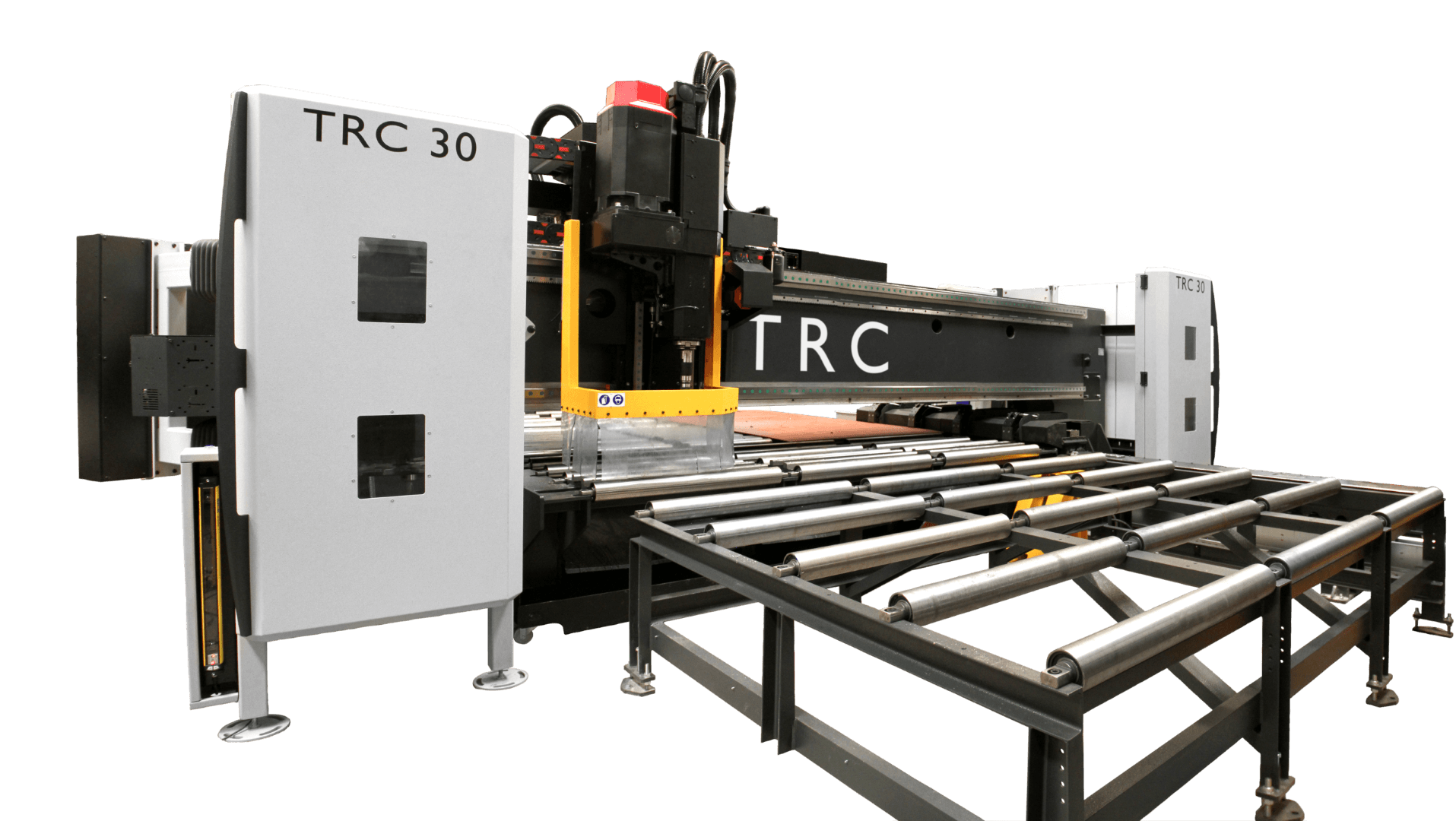

TRC model is designed for intensive use in which it is required to maintain maximum precision and repeatability in cutting and machining tasks.

In order to guarantee the highest performance of each process, the two working areas are perfectly defined avoiding interferences between both processes.

To ensure the positioning precision of the whole machine, the reduction gear system is cycloid, eliminating any chance of backlash and missadjustments in the motion systems.

Suitable for service centers and steel construction workshops with requirements for cutting jobs as well asbevelling, drilling, threading and marking at one single installation.

-

Maximum working width up to 3.100 mm. (122”)

-

Positioning speed up to 35 m/min. (115 ft./min.)

-

Possibility of two machining heads and two cutting heads.

-

High resistance gantry. 16 tons. (35.500 lb)

-

Spindle power up to 22/30 kW “S1”. and 6.000 rpm.

-

Drilling capacity up to 80/110 mm. (3,2”/4,3”)

-

Tapping capacity from M6 to M40.

-

Equipped with FANUC™ activating and controlling systems.

-

Features S.P.C.® system for total piercing control and S.A.C.® to minimize collision effects

Services Included:

- Delivery

- Installation

- Operator training

- CSA Compliance and Inspection

- 1 Year Manufacturers Warranty on Parts and Labour

Tecoi TRC

- BUILD YOUR OWN

Brand: Tecoi

Series: TRC

Model:

Please fill out your information below and our representatives will connect with your very shortly