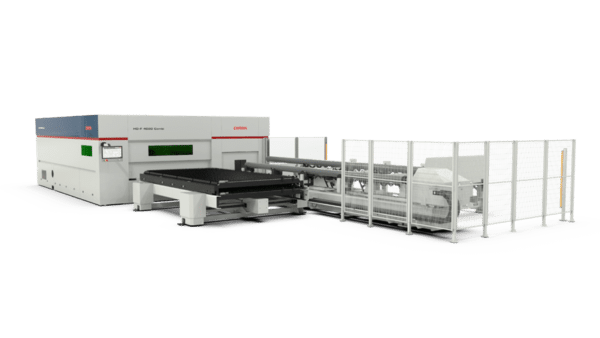

DURMA HD-F Combi

Big tasks? Bigger capacity. Introducing HDF Combi TUBE Flat Fiber Laser.

Designed for a versatile tube-to-flat and flat-to-tube application modified on a whim.

Automated tube feed. Flat table repeatability. Just turn it ON.

The body of the machine is steel, while the bridge is aluminum-welded steel construction. Welded machine body and the axes are processed with stress relief. This process prevents all potential casts that may occur as a result of welding on the machine structure. Moving axes work with dynamic, high-performance AC Servo engines and linear engines that do not require maintenance. A multicellular suction system is used to vacuum the dust generated during the laser cutting process, and to send the dust to dust filters. All scrap parts and small parts that fall to the bottom during cutting are collected and dropped into scrap boxes within the shortest time with a vertical conveyor system.

- Rack and Pinion Motion System

- Tube Cutting Device Side max. Ø170 mm

- CE – Automatic Shuttle Table (Photocell) Safety Light Guards\

- Central lubrication

- Multi Chamber Exhaust System

- Transformer 220,440,575V

- Control Unit SINUMERIK 840D

- Automatic Focus Laser Head Precitec Procutter 2.0 F150

- DURMA Cloud Pro Licence (File transfer & IP Camera included)

- CAD/CAM Software with Autonesting Lantek or Metalix MT Software Licence

Services Included:

- Delivery

- Installation

- Operator training

- CSA Compliance and Inspection

- 2 Years Manufacturers Warranty on Parts and Labour

technical-data-durma-hd-f-combi.pdf(193.86 KB)

technical-data-durma-hd-f-combi.pdf(193.86 KB)

LAZER_EN_V17-1-2.pdf(48.67 MB)

LAZER_EN_V17-1-2.pdf(48.67 MB)

DURMA HD-F Combi Fiber Laser

Big tasks? Bigger capacity. Introducing HDF Combi TUBE Flat Fiber Laser.

Designed for a versatile tube-to-flat and flat-to-tube application modified on a whim.

Automated tube feed. Flat table repeatability. Just turn it ON.

HD-F Combi Automated

- BUILD YOUR OWN

Brand: Durma

Series: HD-F Combi

Model:

Please fill out your information below and our representatives will connect with your very shortly